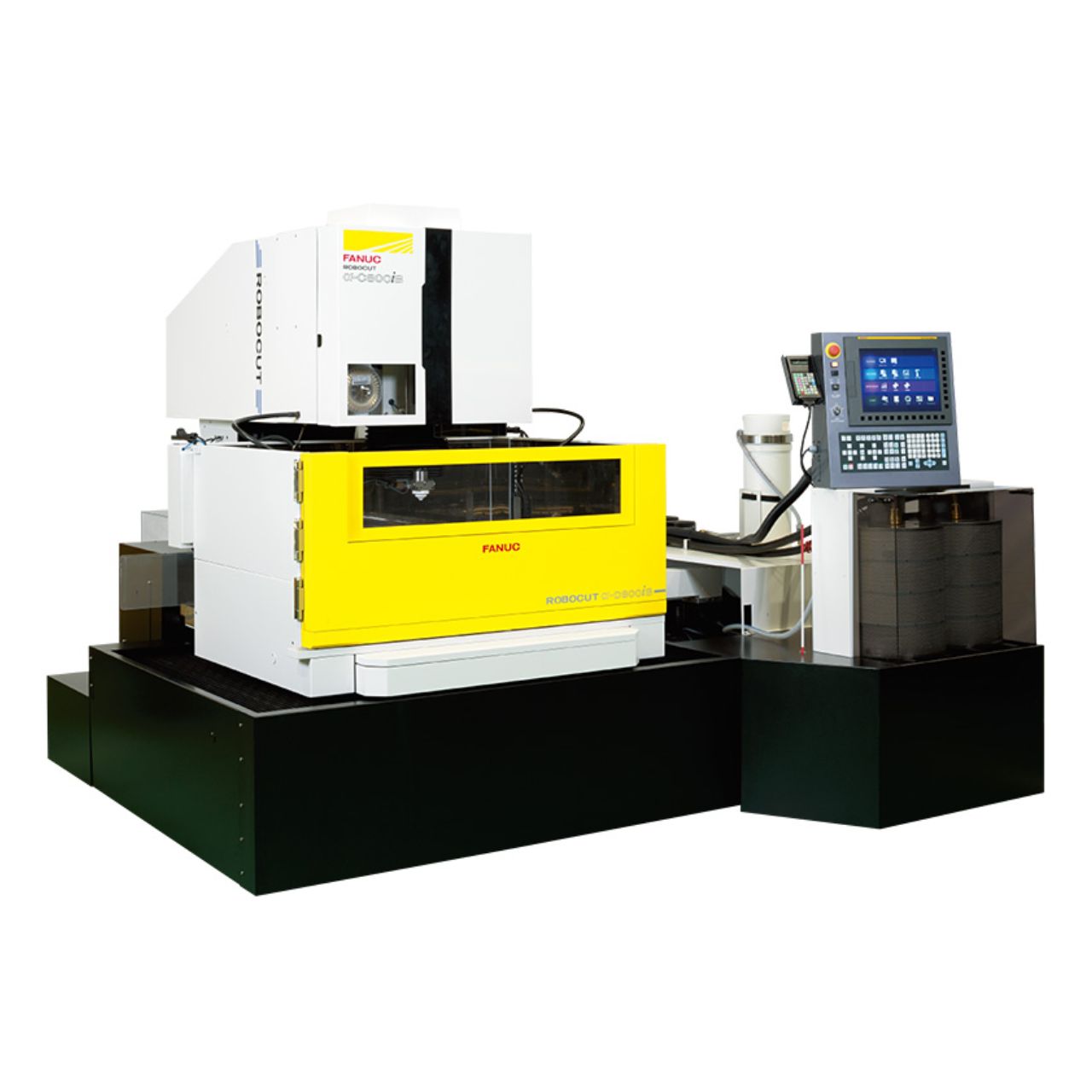

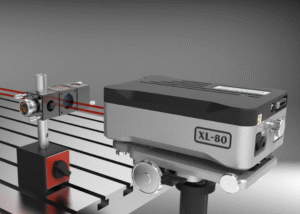

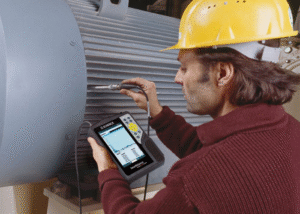

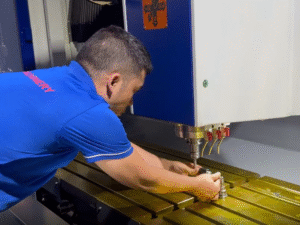

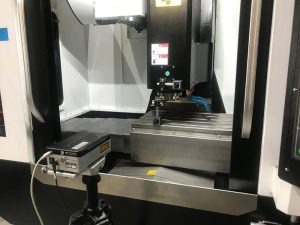

ATC MACHINERY’s technical department is staffed with a team of highly experienced experts who possess in-depth knowledge of industrial machinery. With many years of operation, we consistently ensure superior technical quality, supporting customers in optimizing operations and improving production efficiency.