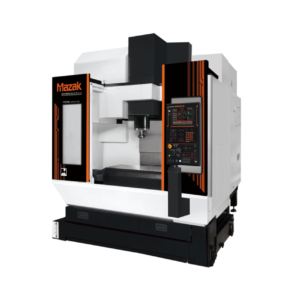

Product Description

Are you looking for a next-generation vertical machining center with high precision and outstanding durability? Then don’t miss the Mazak VCE-700C L. With a large working table, superior torque, and high spindle speed, this machine is ideal for both single-piece and mass production machining.

Outstanding Features

Compared to other products in the same segment, the Mazak VCE-700C L stands out for its ability to machine hard materials. It offers superior stability and durability, designed to withstand heavy cutting forces, and comes with many remarkable advantages.

- THERMAL SHIELD Technology: Helps maintain machining accuracy during continuous operation by minimizing thermal deformation.

High spindle speed: Reaches 10,000 rpm, increasing productivity and reducing machining cycle time. Suitable for various materials such as aluminum, steel, and cast iron. - Rigid machine structure: Designed using Finite Element Analysis (FEA) and 3D simulation to ensure high stability and minimize vibration during heavy-duty machining.

- Optimized control system: Equipped with the advanced MAZAK FZ CNC control, providing an intuitive and user-friendly interface.

- Flexible tool changing: The Mazak VCE-700C L features an automatic tool changer with an exceptionally fast tool change time of only 2.2 seconds.

Benefits

- Optimized productivity: With superior machining speed, the machine increases efficiency and saves production time.

- Consistent product quality: Capable of machining complex components with high precision, ensuring excellent product quality.

- High durability: The VCE-700C L is designed for longevity, reliability, and minimal maintenance requirements.

Application Fields

The Mazak VCE-700L can meet precision machining and mass production requirements. It is suitable for a wide range of industries, including automotive, mold manufacturing, medical equipment, and aerospace.